Process Equipment: Flexible Solutions for Cooling and Solidification Systems

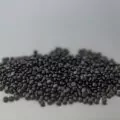

Berndorf, August 2022 – Berndorf Band Group positions itself as a total solution provider, able to offer its customers the complete package. From Steel Belts and Belt Systems, right up to Service and know-how, we cover all areas. That’s why we are a reliable partner for companies all over the world. We place great emphasis on feasibility studies and tests so that your processes function optimally with Berndorf Band Group’s products. This proves our commitment to the engineering, design, manufacture, construction, and installation of your Cooling and Solidification Systems. This extensive approach has proven successful: around the globe, companies rely upon our Single and Double Belt Cooling Systems to solidify sulphur, waxes, resins, oleo chemicals, and many more. And the end products that can be produced on our machines are as diverse as our industries.