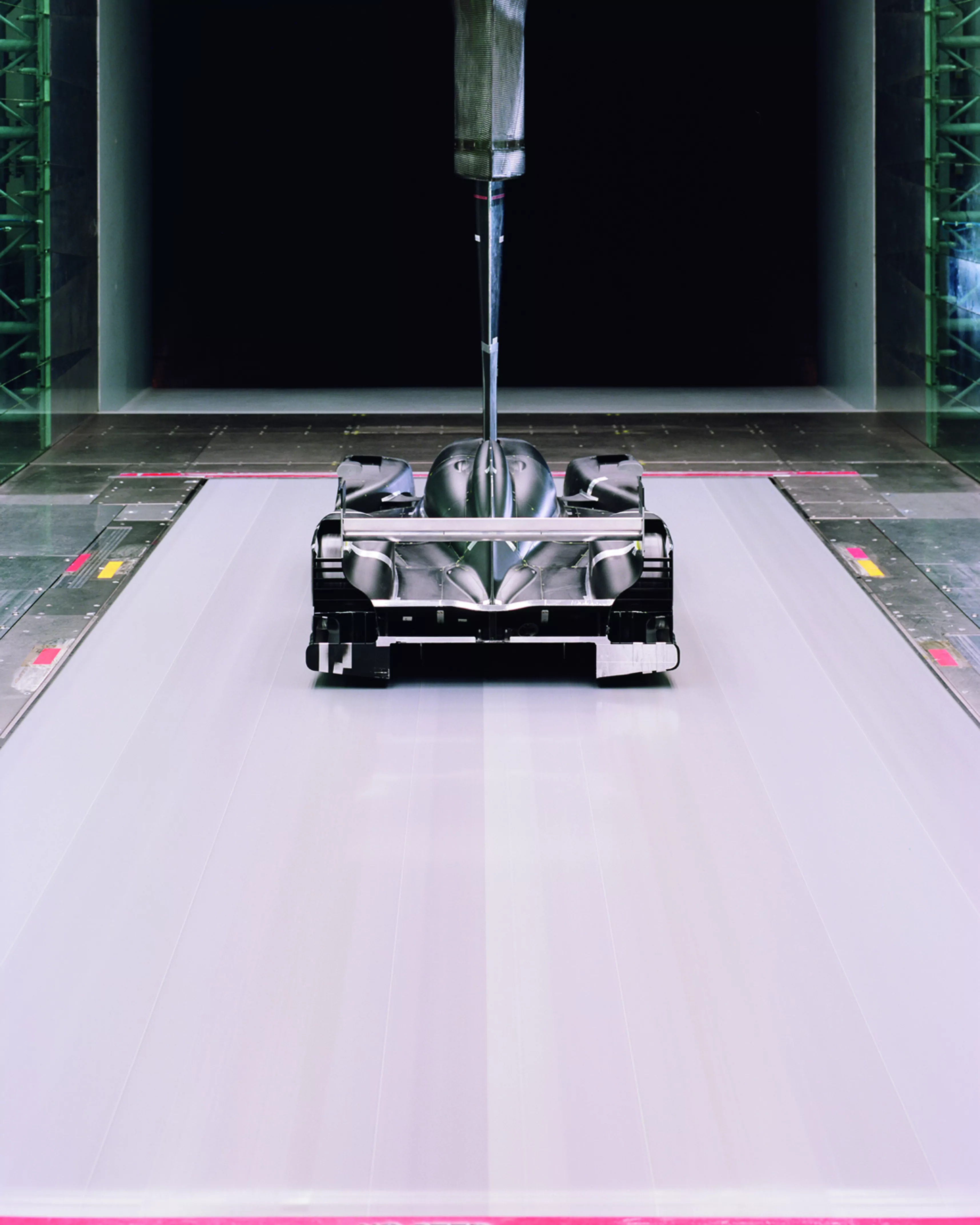

Test Applications

HIGH-END STEEL BELTS FOR TESTING IN VARIOUS INDUSTRIES. As a specialist for high-quality stainless steel belt processing, the Berndorf Band Group manufactures Steel Belts with an exceptionally long lifetime that are ideally suited for applications in the automotive industry. Our Steel Belts are used in demanding tire tests, complex wind tunnel analyses and comprehensive vehicle design processes. The test systems used for these applications are composed of extremely durable stainless Steel Belts, which can sustain speeds of up to 350 km/h | 217 mph.