Cooling & Solidification Systems

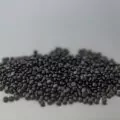

Berndorf Band Group specializes in premium Steel Belts and Cooling & Solidification Systems for global industries processing chemicals, sulphur, sulphur bentonite, powder paint, and more. Committed to excellence in performance and reliability, we excel in designing, constructing, installing, and maintaining tailored Single- and Double Belt Coolers. Our offerings include a wide range of Feeding- and Discharging Devices, ensuring comprehensive solutions. Additionally, we provide solutions for the handling of pastilles or flakes, plus customizable bagging systems.